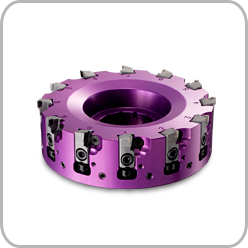

Description

The MFPN series is a high-performance 45° face milling cutter that utilizes double-sided inserts with 10 cutting edges, designed for cost-efficient and high-productivity machining. With its optimized cutting geometry, this cutter reduces cutting forces, improves surface finish, and extends tool life, making it ideal for a wide range of materials including steel, stainless steel, cast iron, and non-ferrous metals.

Double-Sided 10-Edge Insert Design

- Maximizes tool life with 10 effective cutting edges per insert, reducing machining costs.

- Provides excellent wear resistance for prolonged performance.

45° Approach Angle for Smooth Cutting

- Ensures lower cutting forces, reducing vibration and improving surface finish.

- Minimizes burr formation and workpiece stress, making it ideal for finishing applications.

High Feed & Depth Capabilities

- Designed for both roughing and finishing operations.

- Can handle deep cuts with excellent chip evacuation.

Strong Cutting Edge for Stability & Durability

- Rigid insert design ensures better stability in heavy-duty machining

-

Reduces insert chipping and improves tool reliability.

Versatile Material Compatibility

- Suitable for machining steel, stainless steel, cast iron, and aluminum.

- Works effectively in dry and wet machining conditions.

Cost-Effective Milling Solution

- More cutting edges per insert lower overall production costs.

-

Extended tool life results in fewer tool changes and increased machine uptime.