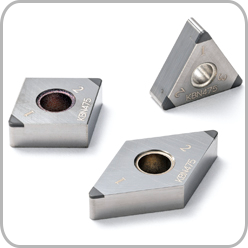

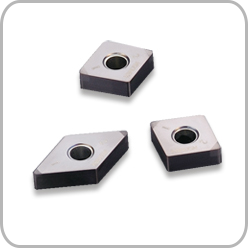

Description

Recommended for high speed machining in cast iron. High CBN content rate reduce abrasive wear and bring stable machining. Special binder improve heat resistance and prevent crater wear.

Application :

- Finishing to Semi-Finishing of Cast Iron

- Optimized for Continuous & Light Interrupted Cutting

- High-Speed Machining with Excellent Surface Finish

- Stable Cutting with Reduced Tool Wear

Advantages:

- High CBN content realized the abrasive wear reduction and stable machining of cast iron

- Special binder improves the heat resistance and prevents the crater wear

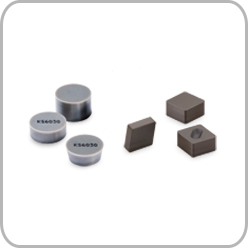

- Wide selection of edge preparation

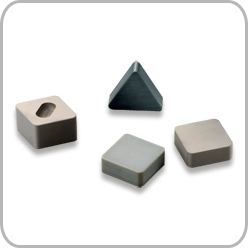

Insert Material & Coating :

- Material: CBN (Cubic Boron Nitride) – Ultra-hard material for extreme wear resistance.

- Coating: Uncoated (CBN Solid Tip) – Maximum thermal stability and durability.

Workpiece Material Compatibility :

- Gray Cast Iron (GCI) – High-speed continuous cutting

- Ductile Cast Iron (Nodular Cast Iron, DCI) – Stable performance in light interrupted cutting

- Hardened Cast Iron – Machining of high-hardness cast iron components