Description

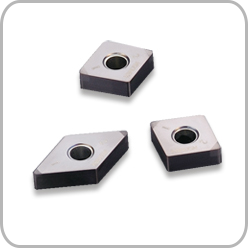

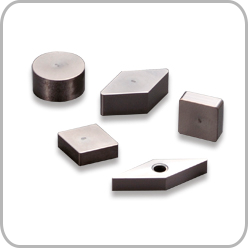

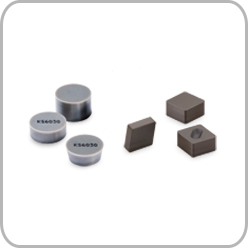

Kyocera’s KBN05M is a Cubic Boron Nitride (CBN) insert grade specifically engineered for machining hardened steels and materials with high hardness. CBN, second only to diamond in hardness, offers exceptional wear resistance and thermal stability, making it ideal for high-speed finishing and interrupted cutting applications.

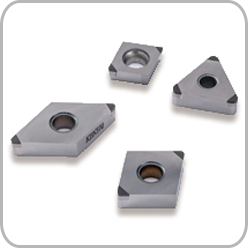

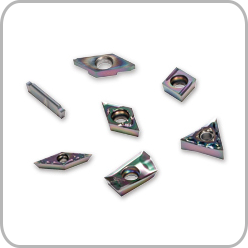

- MEGACOAT Technology: The KBN05M grade utilizes Kyocera’s proprietary MEGACOAT, a heat-resistant PVD coating applied over a highly heat-resistant CBN substrate. This combination significantly enhances wear and oxidation resistance, leading to prolonged tool life and consistent performance.

- Versatile Applications: KBN05M is suitable for a wide range of operations, from continuous high-speed finishing to interrupted machining of hardened materials. Its robust design ensures reliable performance across various cutting conditions.

- Economical Design: The introduction of double-sided multi-edge inserts in the KBN05M lineup provides an economical solution by maximizing the number of cutting edges per insert, thereby reducing overall tooling costs.

Technical Specifications:

Material: Cubic Boron Nitride (CBN) with MEGACOAT PVD coating.

Hardness: CBN possesses high hardness, toughness, and thermal resistance characteristics.

Insert Shapes: Available in various shapes, including CNGA and DNGA, to accommodate different machining requirements.