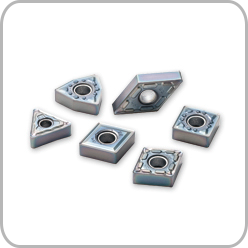

Description

Kyocera’s WP Chipbreaker is designed to enhance machining performance, particularly in operations involving positive inserts. The integration of a wiper edge in these inserts offers significant improvements in surface finish and machining efficiency.

Key Features:

- Wiper Edge Design: The innovative wiper edge geometry allows for high-quality surface finishes even at increased feed rates, effectively enhancing productivity without compromising quality.

- Enhanced Chip Control: The WP Chipbreaker ensures stable chip evacuation, preventing issues like chip entanglement and surface tearing. This stability is maintained across a wide range of feed rates, from low to high-feed machining scenarios.

- Low Cutting Force: The design emphasizes reduced cutting forces, enabling high-precision finishing and minimizing potential damage to the workpiece.

Advantages:

-

Improved Surface Finish: The wiper edge allows for enhanced surface quality without the need to reduce feed rates, thereby maintaining productivity.

-

Increased Productivity: By permitting higher feed rates without sacrificing surface quality, the WP Chipbreaker contributes to more efficient machining processes.

-

Versatility: Suitable for a wide range of applications, these inserts can be used effectively in various machining operations, including turning and boring.