Description

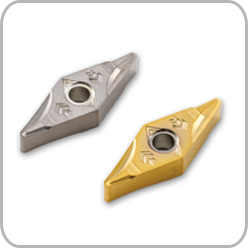

Kyocera provides high-performance insert grades specifically designed for difficult-to-cut materials, such as heat-resistant alloys, titanium alloys, and high-strength stainless steel. Below is an explanation of the PR13 Series and SW Series:

1. PR13 Series (PR1305, PR1310, PR1325) – For Heat-Resistant Alloys & Stainless Steel :

The PR13 Series features MEGACOAT technology, which offers excellent wear and heat resistance, making it ideal for machining heat-resistant alloys such as Inconel, Stellite, and high-strength stainless steel (SUS630, SUS316, etc.)

PR13 Series Advantages:

- Fine Edge Treatment (FET) → Ensures longer-lasting cutting edge sharpness.

- MEGACOAT Coating → Increases hardness up to 30 GPa, extending insert life when machining hard materials.

- High stability during cutting → Reduces tool wear and breakage risks during machining.

PR13 Series Variants:

- PR1305 → For finishing operations on heat-resistant alloys.

- PR1310 → For semi-roughing operations on tough materials.

- PR1325 → For roughing operations on difficult-to-machine materials.2. SW Series – For Titanium Alloy Machining

2. SW Series – For Titanium Alloy Machining

The SW Series is specially developed for machining titanium alloys, which are known for being difficult to cut due to their hardness and tendency to cause built-up edge (BUE) on inserts.

SW Series Advantages:

- Special carbide substrate → Enhances insert wear resistance.

- Reduced cutting friction → Prevents overheating and premature wear.

- Optimized for titanium machining → Provides greater stability compared to standard inserts.

3. PR1535 – For Various Difficult-to-Cut Materials

PR1535 is a MEGACOAT NANO grade with superior strength, designed for heat-resistant alloys, titanium, and stainless steel machining.

PR1535 Advantages:

- Higher resistance to chipping and fractures → Prevents tool breakage in demanding cutting conditions.

- Superior heat resistance → Allows machining at higher speeds without excessive wear.

- Versatility → Suitable for various machining conditions, including S35 (titanium), M35 (stainless steel), and P35 (steel applications).