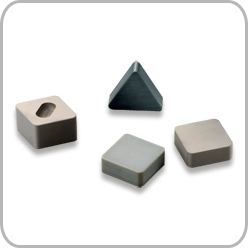

Description

Silicon Nitride (Si₃N₄) ceramic cutting tools have become a top choice for cast iron machining due to their high heat resistance, exceptional wear resistance, and ability to perform at high cutting speeds. The KS6015, KS6050, and CS7050 series offer optimal performance for various applications in the automotive, aerospace, and general manufacturing industries.

Advantages of Silicon Nitride Ceramic for Cast Iron

- High Heat Resistance – Enables dry machining at high speeds without loss of strength.

- Superior Wear Resistance – Longer tool life compared to conventional carbide tools in cast iron machining.

- Excellent Thermal Shock Resistance – Withstands extreme temperature changes during cutting.

- Increased Production Efficiency – Faster cutting speeds reduce downtime and improve output.

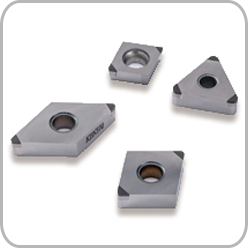

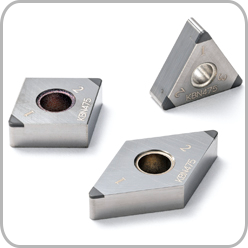

Specifications & Applications of KS6015, KS6050, CS7050

- KS6015 : High wear resistance, stable performance at high speeds, Ideal for finishing and semi-finishing cast iron

- KS6050 : Balanced wear resistance & toughness, Suitable for roughing and finishing in dry or minimal coolant conditions.

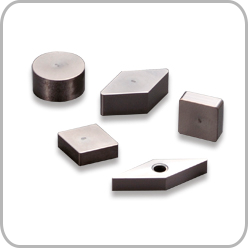

- CS7050 : Extra toughness, best thermal shock resistance, Recommended for heavy roughing and interrupted cuts in cast iron.

Industrial Applications

Automotive – Machining engine blocks, brake discs, and other cast iron components.

General Manufacturing – Mass production of cast iron parts.

Aerospace – High-efficiency machining of heat-resistant materials.