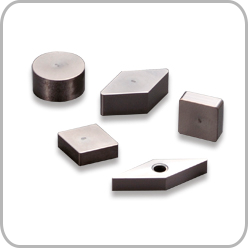

Description

Achieve a long tool life comparable to CBN grade by adopting MEGACOAT. Excellent cost efficiency for high hardness material machining. Excellent wear resistance in high-speed machining of gray cast iron.

The PT600M ceramic cutting tool is engineered for high-hardness material machining, offering superior wear resistance, extreme heat tolerance, and enhanced cutting stability. It is ideal for industries requiring precision machining of hardened steel, superalloys, and other tough materials.

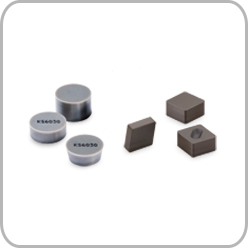

Features :

- Long tool life by MEGACOAT

- Excellent cost efficiency for high hardness material machining

- Excellent wear resistance in gray cast iron machining

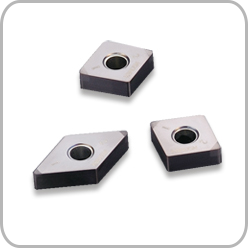

Applications of PT600M

- Hardened Steel (HRC 55-65) : Finishing and semi-finishing of die and mold components.

- Superalloys (Nickel, Cobalt, Titanium Alloys) : High-speed machining for aerospace and energy industries.

- Tool Steels : Precision cutting for tool and die manufacturing.

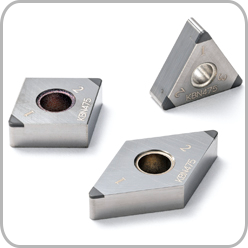

Advantages of Using PT600M

- Extended Tool Life – Reduces replacement frequency and machining downtime.

- High-Speed Machining Capabilities – Enhances productivity with increased cutting speeds.

- Improved Surface Finish – Delivers superior precision for high-hardness components.

- Reduced Heat Generation – Enables dry cutting, minimizing cooling requirements.