Description

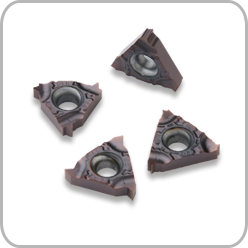

Kyocera’s GBA Grooving System is a versatile solution designed for both external and internal grooving applications. Featuring inserts with three cutting edges, this system offers enhanced cost efficiency and performance across a broad range of machining tasks.

MULTI BUMP DESIGN

- Smooth chip control due to optimum bump placement on the chipbreaker.

- Good chip control for a wide range of applications.

- Sharp cutting edge and MEGACOAT PR1215 provides excellent surface finish.

- Stable machining on automated production lines (prevents frequent machine alarms).

Versatile Insert Grades:

- PR1215: General-purpose grade offering a balance between hardness and toughness.

- PR1625: Features high hardness and toughness, suitable for stable machining in various applications.

- PV7040: A MEGACOAT cermet grade that achieves excellent surface finishes.

Advanced Coating Technologies:

- MEGACOAT NANO EX: This innovative multi-layered coating enhances insert durability and maintains superior cutting performance over extended use.

- PR20 Series Grades: Specifically developed for the GBA system, these grades ensure precision and longevity in grooving operations.

System Components:

- External Grooving Holders: Designed for stability and precision in external grooving tasks.

- Internal Grooving Holders: Engineered to accommodate internal grooving operations, ensuring consistent performance across various applications.

Download PDF Catalogue for this product info.