Description

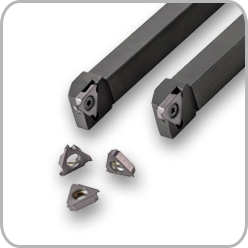

Kyocera’s Goose-Neck Holders are specialized toolholders designed for high-precision machining on automatic lathes, particularly Swiss-type machines with gang-type tool posts. These holders are engineered to enhance productivity and machining quality in small parts manufacturing.

- Integrated Roughing and Finishing: Allows both roughing and finishing operations without retracting the workpiece into the guide bush, reducing cycle times and improving surface finish.

- Enhanced Chip Control: The design prevents chips from entering the guide bush, minimizing potential damage and ensuring consistent machining quality.

- Optimized Chip Evacuation: The holder’s geometry provides ample space for chip evacuation, reducing the risk of chip clogging and enhancing overall machining stability.

- Versatile Design Options: Available in various configurations, including straight, goose-neck, sub-spindle, and Y-axis styles, to accommodate different machining requirements.

- Coolant-Through Capability: Some models support internal coolant delivery, directing coolant precisely to the cutting edge to improve tool life and chip control.

Compatible Inserts

- TKFB Inserts: Suitable for back turning operations.

- TKF-GTP and TKF-AGT Inserts: Designed for grooving and traversing applications.

- TKFT Inserts: Ideal for threading tasks.