Description

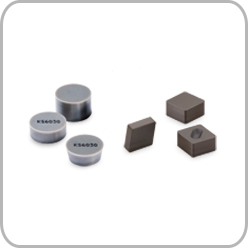

Kyocera KS6030 and KS6040 are SiAlON ceramic inserts specifically designed for machining heat-resistant superalloys such as Inconel, Waspaloy, and nickel-based alloys. These grades offer excellent wear resistance, toughness, and thermal stability, making them ideal for high-speed machining of difficult materials.

KS6030 – For Finishing to Medium Roughing

- Superior Wear Resistance: High chemical stability provides excellent wear resistance, making it ideal for semi-finishing and profiling at medium to high cutting speeds.

- Notch Wear Resistance: Effectively prevents burr formation and chipping, ensuring smooth machining performance.

- Versatile Applications: Suitable for both turning and milling of heat-resistant alloys.

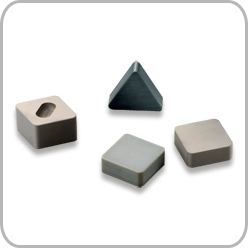

KS6040 – For Roughing

- Enhanced Fracture Resistance: Features hard and acicular grains, improving resistance to fractures and wear.

- Cost-Effective Alternative: Provides a lower cost per part compared to whisker-reinforced ceramics without sacrificing performance.

- Optimized for Roughing: Designed for lower cutting speeds and higher feed rates, making it ideal for roughing applications.