Deskripsi

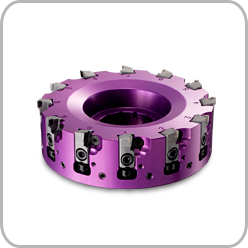

The Kyocera MFH Micro is an extra-small diameter high-feed milling cutter engineered for precision machining in confined spaces. Designed to replace solid end mills, it offers enhanced efficiency and cost-effectiveness.

- Low Cutting Forces: The MFH Micro’s design minimizes cutting resistance, ensuring stable machining and reducing the risk of tool deflection.

- Versatile Machining Capabilities: Capable of handling various operations such as circular milling, ramping, and plunging, making it suitable for complex machining tasks.

- Excellent Chip Evacuation: Optimized geometry facilitates efficient chip removal, preventing clogging and enhancing surface finish quality.

- Cost Efficiency: By replacing solid tools with indexable inserts, the MFH Micro reduces tooling costs and increases productivity.

Specifications

- Cutter Diameters: Available from Ø8 mm to Ø16 mm, accommodating a range of small-scale milling applications.

- Maximum Depth of Cut: Up to 0.5 mm, suitable for high-feed machining with shallow cuts.

- Shank Types: Options include plain shank and threaded types, providing flexibility for different machine tool interfaces.

- Through-Coolant Capability: Designed with internal coolant channels to enhance cooling and chip evacuation during machining.

Applications

- Small Parts Machining: Ideal for industries requiring precision in miniature components, such as electronics and medical device manufacturing.

- High-Feed Milling: Suitable for operations demanding high material removal rates with shallow depths of cut.

- Complex Machining Operations: Effective in performing tasks like circular interpolation, helical milling, and ramping in tight spaces.