Deskripsi

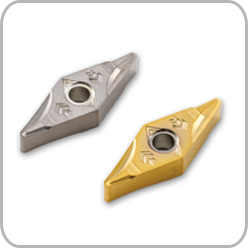

Kyocera’s CA3 Series represents a line of CVD-coated carbide inserts specifically engineered for efficient and reliable machining of cast iron materials. These inserts are distinguished by their rose gold coating, which not only enhances aesthetic appeal but also signifies advanced technological improvements.

Key Features:

- Enhanced Coating Adhesion: The CA3 Series boasts improved coating adhesion, which prevents chipping and ensures stable machining operations. This advancement contributes to longer tool life and consistent performance.

- Micro TiCN Coating: Incorporation of a micro-structured Titanium Carbonitride (TiCN) layer provides excellent wear resistance, allowing the inserts to maintain their cutting edge integrity over extended periods.

Specialized Grades for Diverse Applications:

- CA310: Optimized for high-speed continuous machining of gray cast iron, offering superior wear resistance.

- CA315: Designed for both continuous and interrupted machining of nodular cast iron, providing a balanced combination of wear resistance and stability.

- CA320: Suited for heavily interrupted or high-speed machining of nodular cast iron, this grade enhances stability and extends tool life.

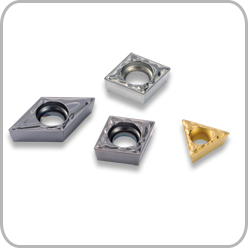

K-Series Chipbreakers:

Advantages:

-

Longer Tool Life: The combination of advanced coatings and specialized grades results in extended tool life, reducing the frequency of insert changes and downtime.

-

Stable Machining: Enhanced coating adhesion and wear resistance contribute to consistent and reliable machining performance, even under varying cutting conditions.

- High Efficiency: The CA3 Series is designed to meet the rising demand for tools that deliver stable performance across a wide range of cutting conditions, thereby increasing overall machining efficiency.

In summary, Kyocera’s CA3 Series offers a comprehensive solution for cast iron machining, addressing the needs for durability, reliability, and efficiency in modern manufacturing environments.